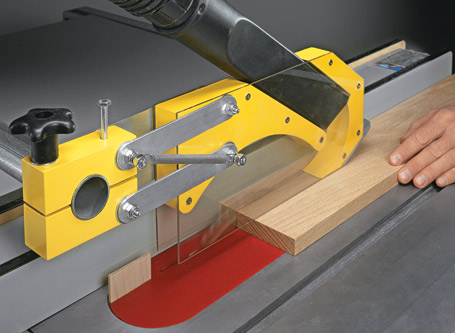

Table Saw Insert

Create a zero-clearance table saw insert to improve safety, prevent kickback, and reduce chipout. Perfect for ripping thin strips with cleaner results.

Make safer, cleaner cuts on your table saw with this easy-to-build zero-clearance insert. Designed specifically for ripping thin strips, this insert replaces the standard factory opening with a slot that matches the exact width of your blade. The result? No more thin offcuts falling into the gap, reducing the risk of dangerous kickback and making your cuts more accurate. It's a smart upgrade that not only protects your fingers but also helps your saw perform at its best.

This woodworking plan guides you through building a custom insert that fits your saw perfectly. In addition to increased safety, the zero-clearance design supports the workpiece right up to the blade, minimizing chipout and delivering cleaner edges on both hardwood and plywood. Whether you're a weekend woodworker or a seasoned pro, this insert is a valuable addition to your workshop. With a couple of clever design improvements over standard inserts, this plan makes it simple to get professional-level results from your existing table saw.

SELECT YOUR PLAN PACKAGE

What You Get:

- 5 pages of step-by-step instructions

- 22 full-color photos and illustrations

Product Recommendations

We don't have any links to project supplies and hardware for this particular project yet, but here are some other products that might be of interest to you. (We may receive commission when you use our affiliate links. However, this does not impact our recommendations.)

Similar Woodsmith Plans

Adjustable Tenon Jig

Build a precision-adjustable tenon jig for your table saw that fits any rip fence and makes cutting tenons safe, accurate, and repeatable.

Taper Jig

Build a fully adjustable taper jig for your table saw. Cut two- or four-sided tapers, straight edges, and angled cuts with accuracy and repeatability.

Dust-Free Blade Cover

Stop table saw dust in its tracks. All it takes is a weekend, some hardware, and an ordinary shop vacuum crevice tool.

Imperial Plans

The United States Customary System of Units (USCS or USC), more commonly referred to as the English or Imperial system, is the standard set of units for our plans. It uses inches and feet for measurement. This is the one you probably want if you are in the United States, and it is the one we have traditionally offered on this website.

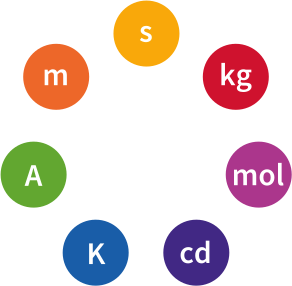

Metric Plans

The International System of Units (SI), more commonly referred to as the metric system, is the alternative set of units that we have available for some of our plans. It uses millimeters, centimeters, and meters for measurement. This is the one you probably want if you are outside the United States. These plans are provided by our business partner, Australian Woodsmith, and are based on the original Woodsmith plan. However, dimensions and other elements of the plan may vary between the metric and standard versions. Be sure to double-check the plan before building.

Premium Plans

All of the information that you need to build our plans can be found in the standard plan. However, if you want even more granular detail to make your job easier, you should consider our premium plans. These come with additional shop diagrams that we drew when creating the prototypes. Shop drawings are not available for every plan.

Gift Plans

We have added the ability to buy plans as gifts for other people. If you enter someone's email address into the gift recipient email box, when you complete your purchase, that plan will be emailed to the recipient you indicated instead of to yourself.

The same plan cannot be purchased for multiple people in the same order. If you are ordering the same plan for multiple people, please place separate orders for each. This is due to the fact that we have built our site with the restriction of 1 product in the cart at any given time, in order to protect people from accidentally placing duplicate orders.

In order to reduce spam emails generated by bots who would purchase and send unsolicited plans to random people, we have restricted gift purchase recipients to people who are already registered on the site. If you wish to purchase a plan as a gift for someone you know, please confirm that they have registered on the site beforehand. For this same reason, free plans cannot be gifted. Otherwise, bots would constantly purchase free plans for random people, who would receive unsolicited emails from us.

There is no need to worry about accidentally buying a duplicate plan for someone who already owns it. If your intended recipient already owns the plan, you will not be able to add it to your cart for them.

If you receive an email that claims to be for a gift plan from someone, please check to ensure that the "from" domain is woodsmithplans.com. Please also check with the person who bought the plan for you, to ensure that it is a legitimate email. Do not open unsolicited email attachments without verifying the email's source first. If you purchase a plan as a gift for someone else, please inform them of this purchase independently so they know to expect the email from us.